Pyramid application briefs.

New installation and retrofit project overviews

Multiple application briefs detail how Pyramid has helped companies in a variety of industries seamlessly integrate, optimize and manage their distribution center (DC) operations.

Multinational Medical Supply Company

► Application Brief

A multinational provider of ventilation devices, technologies and consumables collaborated with Matthews Automation to engineer and implement cutting-edge automation in their U.S. manufacturing and distribution facility. The new systems enable the supplier to consistently package and ship orders with improved accuracy and less labor costs.

Leading E-Grocery Company

► Application Brief

E-grocery order fulfillment is a highly specialized and dynamic process, often involving refrigerated warehouse space. A leading e-grocery brand partnered with Matthews Automation Solutions to automate key tasks throughout their operation and build fast, fresh, and accurate subscription and custom orders.

E-Commerce Apparel Retailer

► Application Brief

A leading .com women’s intimate apparel retailer needed a powerful, flexible warehouse execution system (WES) installed and customized for a facility-wide implementation within its new, greenfield, state-of-the-art order fulfillment distribution center (DC). As the company’s only DC, the facility handles a variety of branded cosmetics, perfumes, personal care items, home décor, footwear, outerwear and clothing.

Intimate Apparel Retailer

► Application Brief

To better support store replenishment, a leading women’s intimate apparel retailer needed a powerful, flexible warehouse execution system (WES) installed and customized. The company also required new material handling equipment (MHE) with Pyramid Controller Series control hardware and software for a retrofit and upgrade at its sole existing store replenishment distribution center (DC), in the Midwest.

Multi-Brand Store, E-Commerce Retailer

► Application Brief

A leading retailer of lingerie, personal care and beauty products, apparel and accessories conducted an enterprise-wide study of its distribution center (DC) operations in an effort to make significant improvements in post-packing to shipping processes. Although such an exercise is common today, this company initiated their study in 1996. Findings included the need to introduce compliance labeling within the outbound supply chain and to automate shipping label printing and application.

Leading Shoe & Accessory Retailer

► Application Brief

A top shoe and accessory retailer needed to update and expand its store fulfillment distribution center (DC) infrastructure in order to keep pace with current and forecasted growth while implementing new business and handling processes. In addition to increasing productivity and efficiency, the company wanted to significantly enhance inventory visibility and implement more precise control methods in order to better meet store needs.

Sports Merchandise, Direct-to-Customer (DTC) Retailer

► Application Brief

Thanks to rapid sales growth and the addition of new product lines, a leading retailer of officially licensed college and professional sports merchandise (and a Top 50 Internet Retailer) needed to significantly expand and modernize the order fulfillment infrastructure and capacity of their new distribution center (DC) for direct-to-consumer (DTC) shipments.

E-Commerce, Autobagger Recontrol

► Application Brief

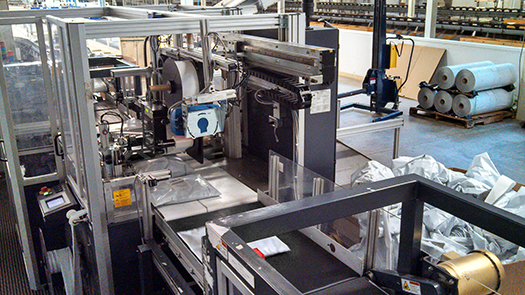

A leading e-commerce apparel retailer needed assistance resolving problems associated with two automated order fulfillment bagging lines (called “autobaggers”). These autobaggers play a critical role in processing the vast majority of the fulfillment center’s single- and multi-line orders by automatically generating an invoice and returns authorization paperwork; combining the invoice with merchandise and marketing collateral; packaging all the items; and printing/applying a shipping label for delivery. Pyramid upgraded and re-engineered automatic bag insertion with Director WCS and customized controls.