After discovering that its post-packing to shipping processes weren’t consistent across each of its seven facilities, a leading retailer of lingerie, personal care and beauty products, apparel and accessories turned to Pyramid.

After discovering that its post-packing to shipping processes weren’t consistent across each of its seven facilities, a leading retailer of lingerie, personal care and beauty products, apparel and accessories turned to Pyramid.

Project goals included higher productivity levels, lower labeling error rates, better ship-to-store service, higher overall throughput network-wide, and compliance with GS1 label standards.

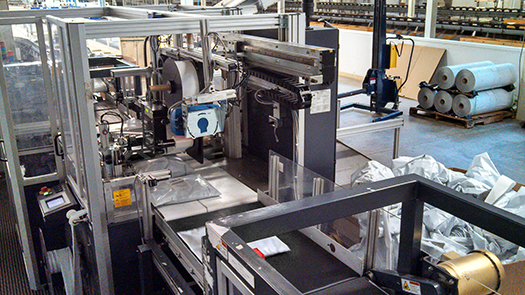

To accomplish those objectives, the company elected to integrate the Pyramid Director Warehouse Control System (WCS) with its Manhattan Associates’ warehouse management system (WMS) and the Pyramid Controller Series (control hardware and software). The resulting combination supervises and directs seven different auto-print/apply implementations operating in parallel over seven facilities. Each installation:

- Includes 1–4 lines, each quipped with 2–3 printer/applicator machines

- Produces standard GS1 compliance labels, including 4 x 6-inch and low-profile 3 x 8-inch sizes

- Achieves peak rates of 50 cases-per-minute per-line, based upon a uniform 30-inch lead-edge to lead-edge pitch, with a minimum 6-inch inter-case gap

- Provides continuous, robust case tracking and control from the point of induction through each case’s exit from the system

- Delivers full process monitoring, diagnostics and operating performance statistical reporting

Each of the seven auto-print/apply systems is associated with a different operating division of the company, and operates independently. All divisions share a common compliance label framework that conforms to the GS1 standard, but each has its own unique marking and labeling requirements and its own WMS.

Director WCS interfaces with the label print/apply machines (in this application ID Technology’s Series 250, equipped with SATO print engines, in all seven facilities) to downloads label templates and variable store data on a per case basis.

The WCS also has advanced print/apply machine configuration and diagnostics, while Pyramid’s Auto-Print/Apply Controller regulates case flow into, through, and out of the print/apply operation, and coordinates the timing of print/apply functions on a per case basis.

Want to learn more? Read the full application brief here.